Our Services

At Decorpanel, we pride ourselves on our comprehensive, full range of offerings including precision veneer cutting and stitching to your exact specifications, and brushing for a flawless finished surface.

In addition, we also provide pressing services to transform your veneers into durable and stunning finished panels. Our panel sanding ensures a smooth and refined finish, while our ability to handle oversized panels caters to your unique project requirements.

Our CNC machines craft intricate designs and shapes with precision and accuracy, adding a touch of sophistication to your projects. Our expertise extends to sourcing uncommon veneers, ensuring that your creations stand out from the crowd.

Veneer

What is veneer?

Wood veneer refers to thin slices of wood bonded onto core panels, known as substrates, resulting in flat sheets. These sheets serve as foundational materials for manufacturing doors, cabinets, wall panels, joinery, and furniture pieces. Utilising timber veneer represents an efficient use of natural resources, as it involves shaving wood from tree trunks. This process ensures that a single log can yield considerable lengths of timber panels. Depending on the slicing angle of the trunk, various grain patterns and features emerge, classified as crown, quarter, or rotary cuts. Wood veneer sheets are compatible with most standard finishing lacquers and stains used for wood surfaces.

Stitching options

Our Natural Veneer range primarily offers book-matched layons, with select options for slip-matched and mix-matched patterns.

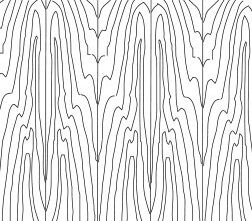

Book matched

Also referred to as paired pattern stitching, this technique produces a symmetrical motif while maintaining veneer continuity.

Slip matched

Also called in-row pattern stitching, the key characteristic of this stitching style is the recurring pattern.

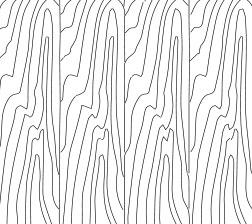

Mix matched

Also known as random pattern stitching, this technique involves combining veneer sheets from various trunks, each with different widths and grain shapes, resulting in a distinctive appearance.

Brushing

By using specialised machinery to create texture on the surface of the veneer, this process typically entails running the veneer through a brushing machine equipped with abrasive brushes that remove softer wood fibers, leaving behind a textured surface. The brushing action enhances the natural grain of the wood, creating a distinctive and tactile finish. Brushing is often used to add depth and character to veneer wood, enhancing its aesthetic appeal and providing a unique visual and tactile experience.

How veneer is cut

The manner in which veneer is cut from the tree significantly influences the final appearance of the veneer panel. Three cutting options are available for consideration.

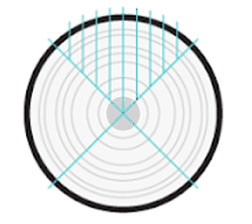

Crown cut

Flat sliced or crown cut through the heart of the log.

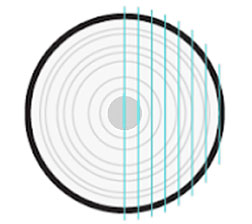

Quarter cut

Straight-grained, cut at rightangles to the growth rings.

Rotary cut

The log is rotated around its axisand peeled off like a carpet roll.

OEM

Decorpanel offers a wide array of substrate options for crafting your custom pressed panels. Utilising our automated lamination facilities, we seamlessly press face materials from our Decorgrain™ timber veneers, Decorluxe™ ASA series, or Decorplus™ HPL series onto your selected substrates. These substrates come in various thicknesses and sizes, ensuring they meet your specific requirements with precision and flexibility.

CNC

We’re proud to offer advanced CNC capabilities in-house, allowing us to harness the technology for precise and intricate veneer woodworking. With our premium CNC machines in house, we have the ability to precisely cut, shape, and carve veneer materials according to your exact specifications.

Whether you need custom patterns, intricate inlays, or precisely cut veneer sheets, our CNC machinery delivers unparalleled accuracy and repeatability. By managing these processes in-house, we ensure strict quality control and efficiency, allowing us to meet your project requirements with precision and speed.

Panel Sanding

This service adds significant value to your project. Our automated sanding facility is capable of thinning wooden surfaces to the desired thickness with precision and efficiency. With the capacity to handle panel sizes up to 3100 x 1300mm, our facility ensures speedy removal of undesired material while providing consistent, uniform thicknesses. This makes it ideal for applications such as wall panels.

Oversized Panels

Oversized panels are a sought-after solution for projects aiming to minimize visible joints and achieve expansive, seamless surfaces. Particularly in high-ceiling environments, oversized side panels enhance visual aesthetics by eliminating unnecessary joining lines. This benefit extends to shop fitters facing similar challenges. Our oversized panels, available in thicknesses of 18mm or greater, cater to various applications, including Decorgrain™ veneer panels, Decorluxe™ ASA panels, and Decorplus™ HPL panels. For precise sizing details and options, please consult with our knowledgeable sales consultants.

CNC

We’re proud to offer advanced CNC capabilities in-house, allowing us to harness the technology for precise and intricate veneer woodworking. With our premium CNC machines in house, we have the ability to precisely cut, shape, and carve veneer materials according to your exact specifications.

Whether you need custom patterns, intricate inlays, or precisely cut veneer sheets, our CNC machinery delivers unparalleled accuracy and repeatability. By managing these processes in-house, we ensure strict quality control and efficiency, allowing us to meet your project requirements with precision and speed.

Sourcing Uncommon Veneers

We specialise in sourcing uncommon veneers to fulfill even the most unique and specific project requirements. Our extensive network and expertise allow us to locate rare and distinctive veneers that may not be readily available elsewhere. Whether you’re searching for exotic wood species, rare grain patterns, or specialised finishes, we’re dedicated to finding the perfect veneer to suit your needs.

Our team works closely with trusted suppliers and utilises our industry connections to source high-quality and distinctive veneers from around the world. We understand the importance of individuality and craftsmanship, and we’re committed to providing you with exceptional veneer options that set your project apart.

Delivery Info

Within Auckland:

Covering Northern areas up to Silverdale, Southern areas up to Pokeno, Western areas up to Kumeu, and Eastern areas up to Flat Bush. Standard delivery entails one driver delivering without offloading, lifting, or removing packages and rubbish. Delivery fees vary depending on your order.

Outside Auckland:

For long-haul shipments outside Auckland, we recommend Mainfreight to our customers. The delivery cost is determined by Mainfreight’s online services based on the volume and weight of your shipment.

Please Note:

Please mark “subject to inspection” on your packing slip if you are unable to inspect the goods before they are shipped.

Lead Time:

For stock items, orders placed before noon will be dispatched the next day. Otherwise, they will be dispatched within the following two days. Non-stock or customised items will be negotiated on a case-by-case basis.

Emergency Orders:

A surcharge of $150 will be applied for urgent deliveries.