Decorgrain Veneer

Timber veneers, sourced from natural log species, undergo processing into uniform sheets using various techniques like crown cut, rotary cut, quarter cut. Each veneer preserves the unique characteristics of wood, including its grain, texture, and gentle touch. Remarkably efficient, one cubic meter of timber yields 1000 square meters of veneer. Eco-friendly and sustainable, timber veneers offer an environmentally conscious option for interior design and furniture.

Products

Natural wood veneer offers a timeless and elegant aesthetic, adding warmth and character to any project. Sourced from a variety of wood species, including oak, maple, walnut, and cherry, natural wood veneer showcases the unique grain patterns and rich colors inherent to each species.

Reconstituted veneer, also known as engineered or reconstructed veneer, offers a versatile and sustainable alternative to natural wood veneer. Made from fast-growing and renewable wood species, reconstituted veneer is crafted through a process that involves slicing, drying, and dyeing wood fibers before pressing them into sheets.

Veneer

What is veneer?

Wood veneer refers to thin slices of wood bonded onto core panels, known as substrates, resulting in flat sheets. These sheets serve as foundational materials for manufacturing doors, cabinets, wall panels, joinery, and furniture pieces. Utilising timber veneer represents an efficient use of natural resources, as it involves shaving wood from tree trunks. This process ensures that a single log can yield considerable lengths of timber panels. Depending on the slicing angle of the trunk, various grain patterns and features emerge, classified as crown, quarter, or rotary cuts. Wood veneer sheets are compatible with most standard finishing lacquers and stains used for wood surfaces.

Stitching options

Our Natural Veneer range primarily offers book-matched layons, with select options for slip-matched and mix-matched patterns.

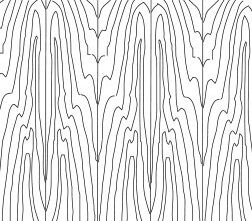

Book matched

Also referred to as paired pattern stitching, this technique produces a symmetrical motif while maintaining veneer continuity.

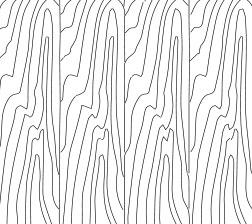

Slip matched

Also called in-row pattern stitching, the key characteristic of this stitching style is the recurring pattern.

Mix matched

Also known as random pattern stitching, this technique involves combining veneer sheets from various trunks, each with different widths and grain shapes, resulting in a distinctive appearance.

Brushing

By using specialised machinery to create texture on the surface of the veneer, this process typically entails running the veneer through a brushing machine equipped with abrasive brushes that remove softer wood fibers, leaving behind a textured surface. The brushing action enhances the natural grain of the wood, creating a distinctive and tactile finish. Brushing is often used to add depth and character to veneer wood, enhancing its aesthetic appeal and providing a unique visual and tactile experience.

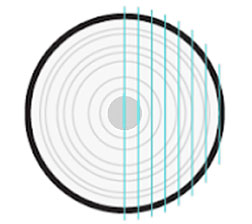

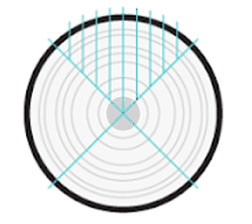

How veneer is cut

The manner in which veneer is cut from the tree significantly influences the final appearance of the veneer panel. Three cutting options are available for consideration.

Crown cut

Flat sliced or crown cut through the heart of the log.

Quarter cut

Straight-grained, cut at rightangles to the growth rings.

Rotary cut

The log is rotated around its axisand peeled off like a carpet roll.